Precision of ASTM C1028-07

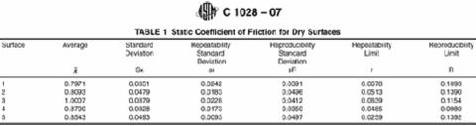

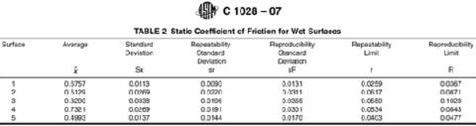

“Precision” consists of repeatability by one person within one laboratory and “reproducibility” between multiple laboratories. Tables 1 and 2 below show repeatability (r) and reproducibility (R) data from the C 1028 method for five different materials chosen for precision testing by the ASTM committee in charge of this test. Table 1 is for dry tests, Table 2 for wet tests. (Click on the tables below to see them in pdf format.)

For wet testing the repeatability limit "r" within one lab is as high as 0.0617 (or 0.06), and the reproducibility limit "R" between laboratories is as high as 0.10. (These maximum numbers could easily have turned out to be higher had more than five tiles been tested.)

One should therefore pay little attention to moderately large differences (like 0.07 or 0.14) in any test results obtained using this method.

The ASTM committee that approved this method affirmed, repeatedly and unanimously or near-unanimously, that this method is not intended to assess slip safety. For assessing real-world floor slip resistance safety based on 50 years of research around the world, the test method needed is ASTM E303, published in 2022, and available in the lab or in the field through Safety Direct America. Safety criteria using ASTM E303 test results for different areas of a building (and outside of them) are included with test reports obtained through the experts in this field of study in the Americas.